I’m starting a new fiction series. More information can be found here:

https://technomancers-sanctum.blog/rals-guide-to-adventuring/

I’m starting a new fiction series. More information can be found here:

https://technomancers-sanctum.blog/rals-guide-to-adventuring/

I’ve been working on a few things crafting-wise lately, none of them too major at the moment.

Minis-Painting:

I decided to paint a few minis again. I’m hoping to print some minis for a game of Shadowrun soon, so while I’ve been tinkering with the printer I’ve been painting a few small things. A couple of minis that wouldn’t be out of place in-genre, and the Mound of Dead Bards from Gamers: Dorkness Rising. That last one took quite a bit of work.

3D printer tinkering:

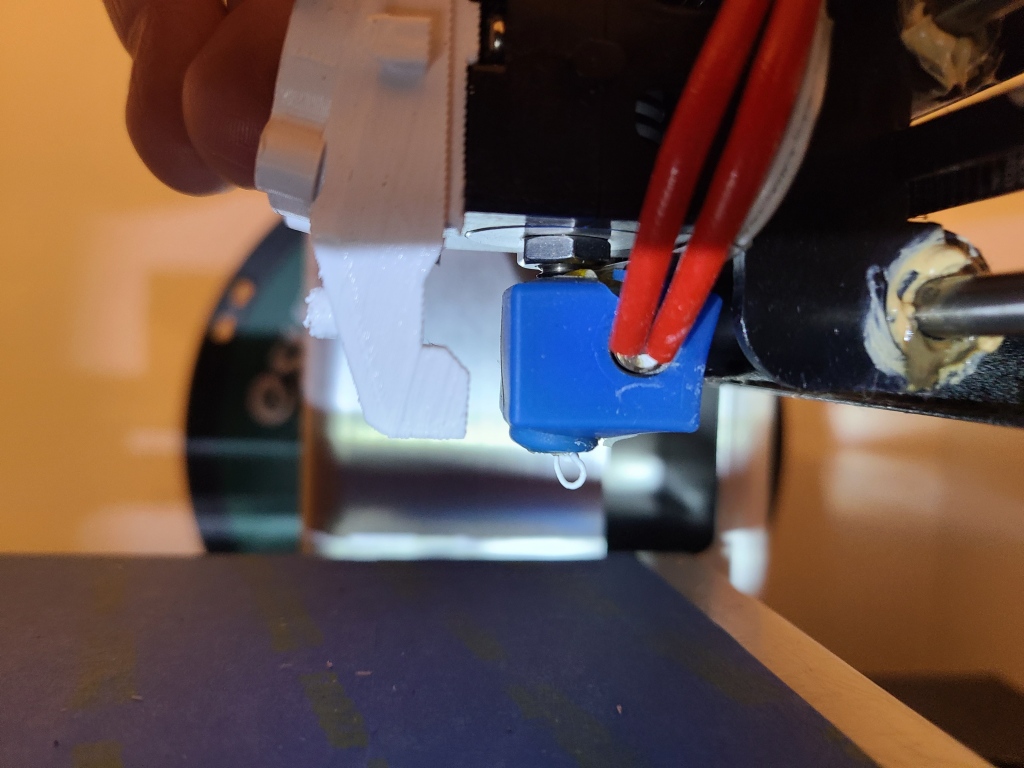

I’ve so far never managed to get the Monoprice Select Mini Pro to print minis as nicely as the other printer. I’ve been tinkering with some settings, and also with the hardware. Main thing I want to change is to improve the part cooling. I’ve gone through a couple iterations of air vent modifications and swapping in a better fan, but I really think it needs 2 fans. Unfortunately all the designs I see that include 2 fans are for different configurations or models, so I’m having to do some model splicing and editing. The main issue I come across is that the bed levelling/z axis sensor is mounted in a specific location not present on earlier versions of the MPSM, so I’m having to carefully splice that mount in in a way that is compatible with the air mods. I’m also doing a bit of experimentation with freehand modifications with the 3d printing pen, but the improvement has not been significant.

Bag of holding repair/upgrade:

I’ve had a bag of holding from Thinkgeek for years. Used it in my college days until I overloaded it with weight and damaged it beyond my ability to repair at the time. I’ve carried it with me from place to place, and occasionally used it (with some safety pins over a busted zipper or two) for thematic appropriateness or something “close enough”.

Recently I came across the bag again, and decided to work on it, inspired by finally going to a tabletop RPG night again. So far I’ve repaired the failed zipper, reinforced all the zippers, and added pull tabs on the zippers to make them open and close more easily. I repaired the fabric where the stitching had been coming loose, such as on the zippers and the strap where it attaches. Since I’m gaming in a high traffic makerspace, and I recall these bags being somewhat common, I’ve been adding patches to make it more identifiable. Most recently I decided to finally test out tge chemical NeverWet, and a “magic bag” seemed an appropriate use of it

I’m currently waiting on the neverwet to dry. I was able to use an old pressure fit curtain rod to hole the bag between two posts for spraying. Thankfully the fumes died down after a while. They were pretty bad, and got throughout my home, even though I sprayed outside.

I keep a wall of hats above my shelves of board games, as kind of a thematic backdrop, especially with the RPGs. One that needed to go on the wall is a pirate hat. However, most of the pirate hats I saw were disappointing to me. For one thing, ever since my childhood, this has been my idea of THE pirate hat:

Dustin Hoffman as Captain Hook in the movie Hook.

So, I decided to make my own version of the hat.

Parts list:

Tools List:

To start with I took the hat, and cut and sewed the gold trim on along the edge, using the gold thread to hide the stitching.

In some places where there was a bit internal curve I had to detail trim some of the lace so it would lay flat and not look too out of place.

As I expected, I would see that I would need to glue and/or stitch the lace points down so they would lay right.

I started brushing on felt glue on the back of the lace, and pinning it into place so that I wouldn’t have to worry about curling or stretching or anything like that.

I let the glue dry for 24 hours, then removed the pins and began stitching some more. Reinforcing the points, some spots I thought were popping up a little, and other parts I thought might need more stitching. Not much to see there except some ugly stitches that I later covered up.

Upon consultation, I realized that the maribou was a bit too thick, and needed to be trimmed to work. I cut it into 3 distinct sections for easier sewing, and then used the pliers to remove alternating groups of feathers. Over time I stitched through the connecting ribbon of the maribou trim into the hat, with some truly atrocious looking stitches. You can also see some of the tack stitches that I used to reinforce the lace and glue.

Tip: when you stitch the maribou through, some adhesive from the ribbon will adhere to the needle, and tiny bits of feather will be pulled through with it. As far as I know you can’t prevent this, but just know that you will need to use your fingernails or maybe some tweezers to pluck those feather bits off. Then run a lint roller over it.

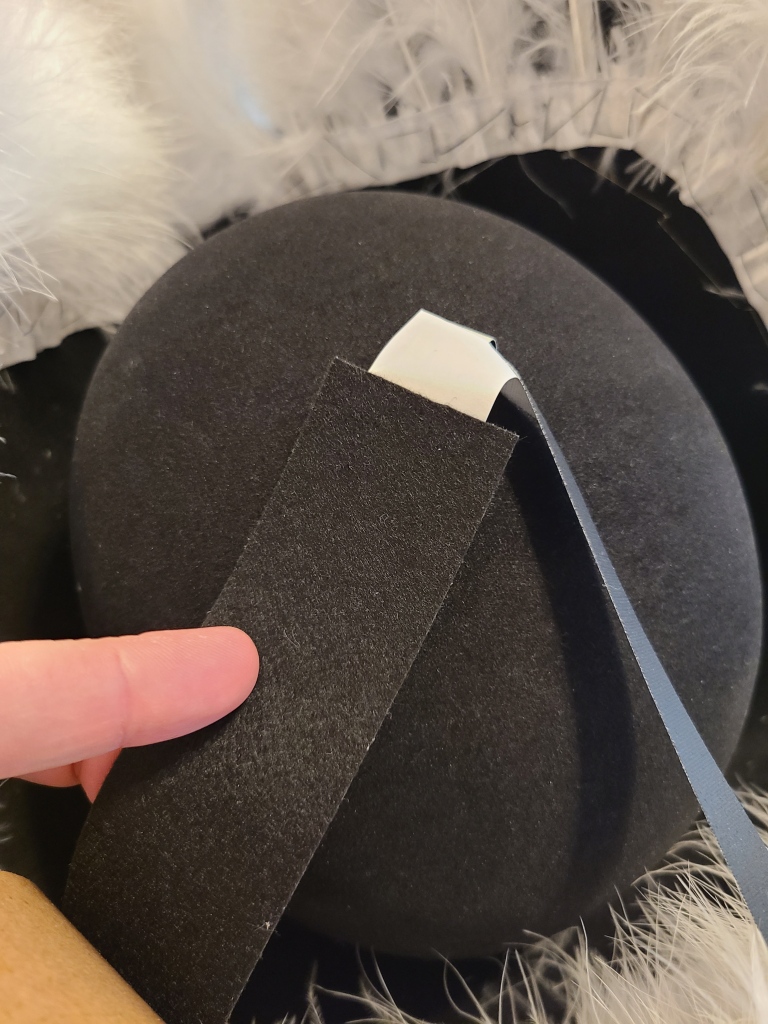

In the spirit of Adam Savage’s philosophy of “hide your costuming crimes,” I decided that the stitching was going to bother me and needed to disappear. If I were just wearing the hat on my head, I probably wasn’t going to care, but my hats hang on a wall facing the living area, so it needed to look a little better. This is when I decided to do some research, and found a black felt adhesive tape that would blend into the hat.

To not end up with a mess with all these light weight feathers sticking to the tape, I prepped by using a hand towel to hold the feathers back with the weight of it.

Then I cut segments of tape to handle the contours of stitching and cover things up. I placed the tape in segments, and then moved to each section in turn.

By the end of it, the stitching was pretty much hidden.

At this point, you’re going to want to use a little bit of painter’s tape to get bits of feather out of the inside of the hat. DO NOT use the lint roller for in there, you will catch it on the feathers that you want to stay on the hat. You may also want to run the lint roller on the outside of the hat.

And now I finally have my pirate captain hat!

And the wall of hats is slightly more complete. Still needs something space themed. I’m thinking there might be a space helmet project in my future.

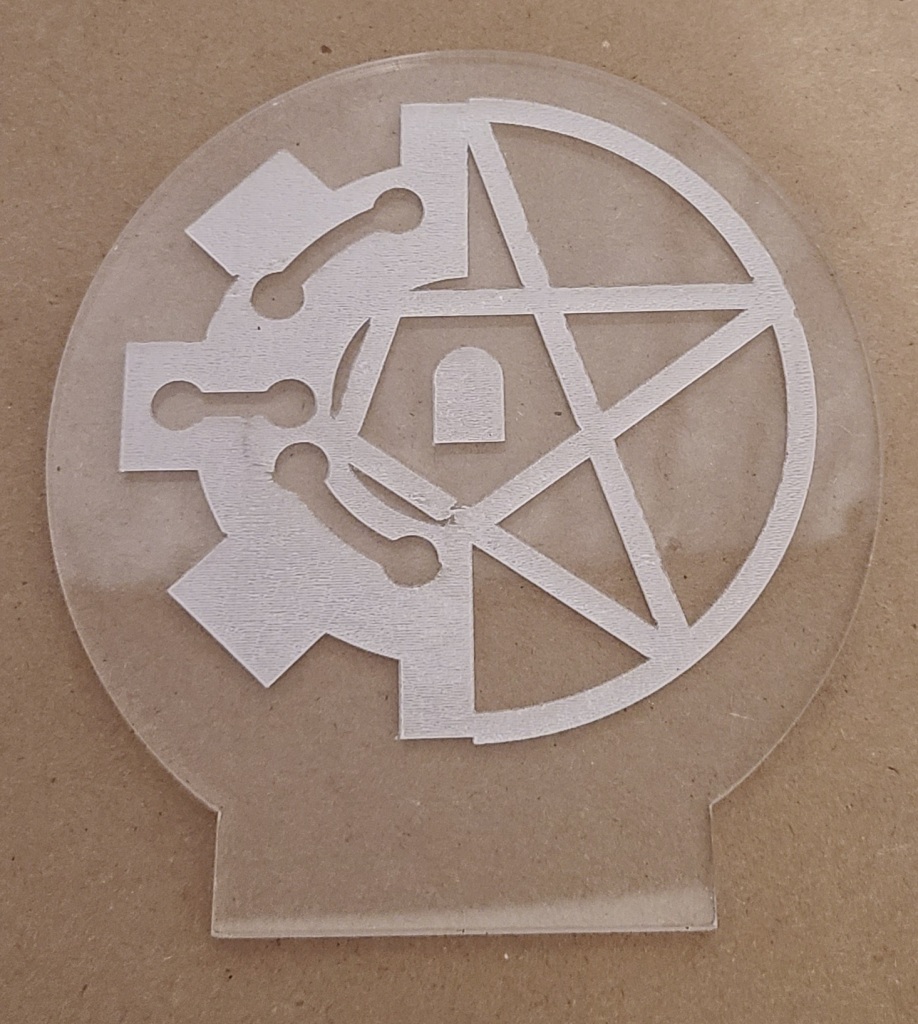

Recently I’ve joined a local makerspace, and started on broadening my experience on a wider variety of tools. Starting with using a laser cutter. So far I’ve gotten my sign-off to use it, and started a couple small projects. One was straightforward, and just got me familiar with the basics. I made myself an edge-lit acrylic sign, using parts from a kit, and just engraving it and assembling.

Pretty straightforward, gives me some themed lighting, and was good for getting a bit more familiar with some of the process of creating my own engraving.

The other laser project has not been going so well. So far I’ve made two attempts to create a two-layer battleboard for carrying around my laptop at the makerspace. I designed the thing in Autodesk Fusion 360, exported the files, got everything set up, and it seemed to be going well. On the first attempt it turned out that I had some settings a bit too fast and lower power, and the wood was rather thick. I went through several passes with the laser, and it still didn’t cut through. I reserved the machine again later to reattempt (had to use a new section of wood because I couldn’t align it to use the same origin as before).

And then the safety latch on the door started malfunctioning and caused the machine to refuse to fire the laser… but did not indicate that in any way. The machine moved in it’s preprogrammed sequence as if it were fine, but after a bit I noticed I didn’t see any more evidence of cutting. No smoke, no flashes of light from the material burning away… and the power usage needle never spiked from the laser firing. So far I’ve just got a neatly scorched piece of wood, and will probably need to purchase and chop another piece to try again. Uggggh.

I’d have tinkered with the machine, but I’m not one of the responsible parties for that equipment at the makerspace.

On the bright side, one of my other side projects is going pretty well.

I’ve started working on my interpretation of Captain Hook’s hat (from Dustin Hoffman in the movie Hook). My wall of hats for themed gaming has been missing a pirate hat, and to me that is the iconic pirate hat, so I’m making my own (using a simpler hat as a base). I’ll have to break that down more later.

So, it’s been quite a while since I’ve posted, and at this rate I’m not sure I’ll be finishing a detailed description of the design and construction process anytime soon, so I’m gonna skip ahead a bit. If there’s enough interest in explaining the portions that I’ve skipped past (or I make myself take the time) I may circle back and explain.

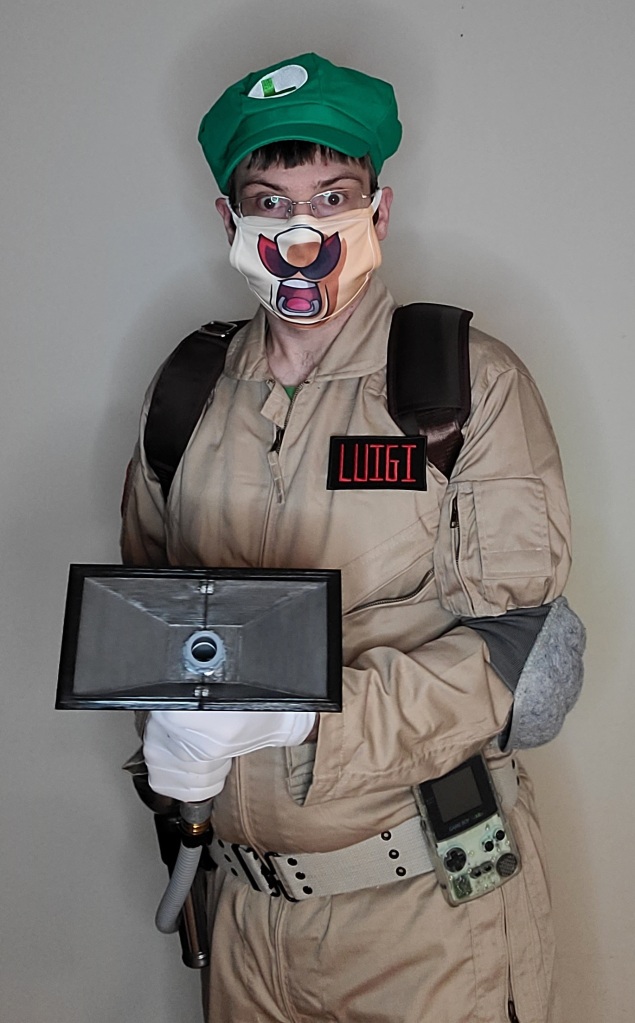

Anyway, here we go. Through a lot of tinkering with 3D models, learning how to perform photogrammetry, and some hands on work, I finally finished the polterbuster, so now I have my completed costume.

I got the hand unit to hang off the side of the pack on the custom made mounting brackets with some magnets. Haven’t yet gotten the straps to handle the pack being unbalanced with the unit on it yet.

And now here’s everything put together. It was finished just in time for Halloween… when there was nowhere to go. Oh well, there’s always the next convention!

Maybe one day I’ll revisit this and get some decent sound effects added to it.

The clear compartment on the original vacuum contained a lot of white foam balls that got blown around by a fan when the toy was turned on. I decided that I was going to install lights here. The Poltergust from the games had one light… but this is an imprecise mashup piece. I decided to go with 4 lights, in homage to the proton packs, but green to match the aesthetic of Luigi’s Mansion.

Here’s what I was working with:

I removed the foam balls, and originally I was also going to chuck the fan in the trash too, but I hold onto parts like that just in case, and I’m glad I did. This will be important for later.

For the lights I ordered some 10mm green LEDs (I like my tech chonky, especially for a cartoon character), and the accompanying resistors.

I 3D modelled and printed a piece to hold them into place in the spacing I wanted, and after a lot of frustration and soldering I got them into the installed. I put a solderless connector on the end so that I can separate parts when troubleshooting and/or if I decided to mount the board on the other half of the casing. I really need to spend some more time practicing crimping those connections correctly.

To control the lights for a blinking pattern, I used a knockoff arduino nano and modified some simple code for it. Gotta watch out for those knockoff boards, though. I had to go find special drivers so I could use the board, which can be nervewracking. You never know what people are going to include in code from an obscure website.

To power the board, I decided to use a phone power bank, as I hoped it would be an easy solution… I should know better.

Hooking the board to the phone bank powered the lights…. for less than a minute. Then the power-saving features on the bank determined there wasn’t actually enough of a load on the circuit, and cut out. After a lot of fiddling with resistors, I added a bundle of 4 resistors in parallel to the circuit to add a little bit of load, which makes the power bank stay on.

Once I had verified that the power bank would stay on, I went to permanently install the components. I continued cannibalizing the cable I was using, and wired the resistor into the circuit. I also added the toy’s original power button into the circuit as it would be a conveniently accessible button already built into the casing.

Of course, the one segment of the wire I HADN’T messed with turned out to have a short. I had to cannibalize another wire end to bypass it. (Not shown, just annoying)

Then I had to figure out how to mount everything so that it would stay in place and function reliably. I went by my old standby for mounting things: hook-and-loop-backed command strips.

I used the modified USB cable to connect the two halves together for closing up. I also added an extension cable for charging the power bank without opening up the case, and a cut a hole for checking the display of the power bank to determine the charge status.

With that all wrapped up and functioning, here’s the light sequence. Pay no attention to the other changes for now.

I need to be able to wear this as a backpack. Conveniently, I found that the bottom had 3 wheels.

I carefully removed the wheels (just required removing the screws), and used the screw holes to mount some connecting rings.

Then I added some padded, adjustable straps. They weren’t quite the right length. The backpack dangled far too low on my back originally.

I ended up having to shorten the straps, cutting the stitches on one end, and restitching them at a better length. The ends dangle, and I’ll probably need to shorten and/or stitch them flat later for neatness, but at least they work now.

It’s not the best stitchwork, but it works well enough. Now the straps are in a range where, if anything, I might need to adjust the straps longer using the built in adjustment hardware. Just about where I wanted it. Shortening these straps didn’t take long at all to do.

I’m starting some overdue updates on the backpack. I’ve decided to call it the PolterBuster for now. Just so I have a tag for these posts, and the build is a mashup of a Poltergust and Ghostbusters equipment.

In the previous post I mentioned where I got some of my inspiration from for the backpack, and showed what I started from.

This should probably usually be last, but I was solving problems as I went. There was a lot of text on the vacuum unrelated to it’s new life as a Poltergust. For the sides, that was an easy enough fix (as long as people aren’t looking TOO closely). I just sanded off the text, colored in the area with a black sharpie, and IMMEDIATELY rubbed off the excess ink with a dry paper towel. Seems to work okay. The same trick KINDA worked for a small section of the text on the red shell and a red sharpie, but I only used it for a small section where I was unable to fully cover up the text.

It’s an interesting trick I learned from a friend of mine. Too bad I realized later that it’s going to get covered up by some other parts as soon as I can make them, but now I have another trick up my sleeve.

For most of the rest of the text and symbols that I didn’t want, I covered them with what I thought were appropriate stickers.

The NES controller sticker covered the hole that a fake knob protrudes from, so I placed the sticker and used a hobby knife to trim the hole out.

I also decided I wanted to cover the fake power cable retraction button.

PEW PEW PEW.

Not much to cover in this particular post, but I’m trying to break these up by topic into manageable chunks.

I’ve been playing a lot of Luigi’s Mansion lately (1 and 2, I don’t have a Switch for 3), and decided to combine costume ideas. Luigi in a modified Ghostbusters uniform.

Base uniform:

I started with the base jumpsuit with the Ghostbuster patches removed.

Then added Luigi’s hat and gloves. Mine is compatible with touchscreens!

Now for some replacement patches. I got the custom name patch from GBFans.com.

And the No Boo version of the No Ghost patch from a vendor on eBay.

Belt & Accessories:

I liked the vintage style flashlight that Luigi carries at the start of the games before he picks up the backpack. I did some hunting on eBay, and acquired this one:

The bulb was dim and flickering, so I decided to replace it with an LED of equivalent size. While I had it open I removed a bit of corrosion from the battery spring and taped the split glass lens together to make it sturdier. I also found a holster to hold the flashlight on my belt.

I also needed Luigi’s version of a PKE meter, the Gameboy Horror. After a bit of eBay auctioning and retrofitting, I’ve got my own! I may cover more of what went into that in another post, but here’s the final result.

There is also a clear plastic clip that was sold as an aftermarket item to match.

I’m using the standard web-belt from the Ghostbusters uniform, so nothing fancy there.

The Backpack:

This portion will definitely require a post or more of it’s own. I’ve acquired most of the parts, but I’ve barely started on construction on it. I’m starting from this toy vacuum cleaner as the base:

I can’t claim credit for this part of the idea. I thought someone had likely tried to build this pack already, and of course someone had. I did a quick search on youtube and came across this video.

I’m not planning on building the pack the same way he did, but it works as a good enough base. Mine is going to be my own interpretation of a mashup between the Ghostbusters proton pack and Luigi’s Poltergust.

Where I am so far:

So, just about everything except the pack is ready. Also, I’m not gonna be grooming the mustache or wearing a fake one, so I’m waiting on a cloth mask with a print of the lower half of Luigi’s face on it!

Here’s what I’ve got together so far:

I think it’s coming together nicely!

I’ve been doing some training to improve my 3D modelling skills with Autodesk Fusion 360 (not sponsored, that’s just what I use) lately, and in one of the videos the instructor mentioned that he happened to like using a 3D mouse to rotate the models and help his workflow be just that bit easier.

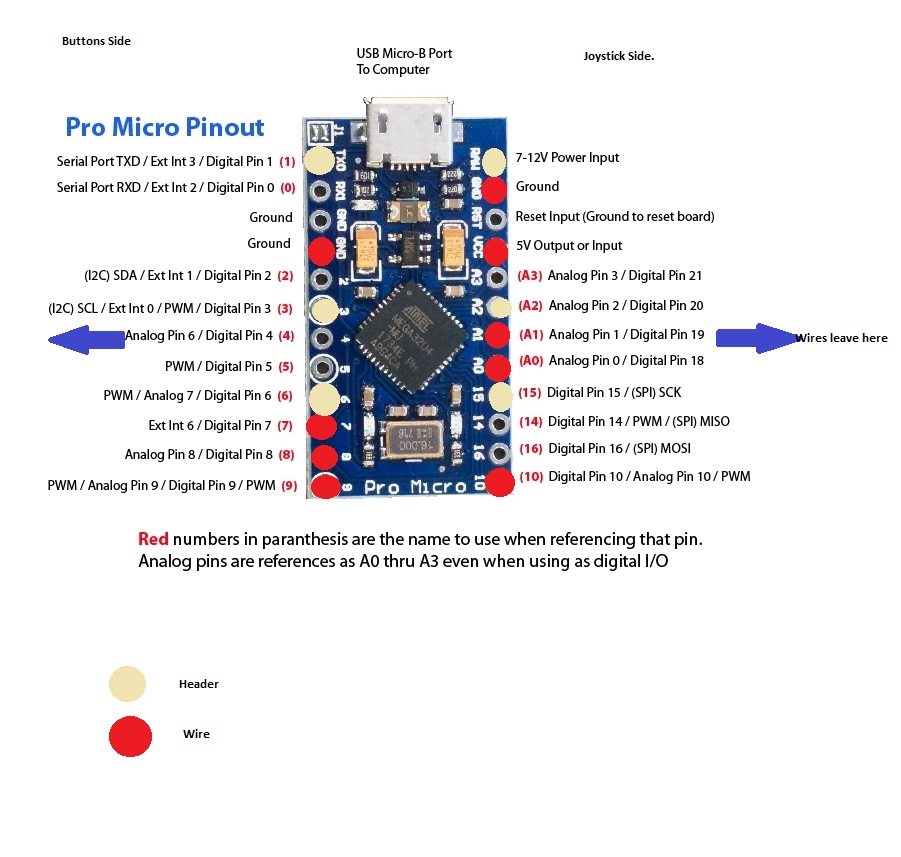

Around the same time, someone happened to drop this link in the cyberdeck discord chat.

https://www.instructables.com/Space-Mouse-With-Arduino-Micro-Fully-Printable/

It’s the instructions for a homemade spaced mouse with 3d printed casing. It uses a small arduino board and some inputs (buttons and a clickable joystick) to make a space mouse.

Hmm… I can build a space mouse for a fraction of the cost of one I could buy? I get a new device for my workflow AND a project to practice a bit more with electronics and code?

Well, that’s a no-brainer. Project ahoy!

So, I started following these instructions, and built my space mouse.

Side note: every time I use the term space mouse I think of Mickey in a spacesuit. I don’t know if anyone else has that issue, but I just had to share.

I don’t think I’m gonna get too in depth covering it, as that feels redundant with the instructable above. I will point out a few things form my experience though.

This project made me very glad that the arduino boards came in a multi pack. I botched the first attempt HARD.

I put pins along the entire length of the soldering locations. Where are the wires supposed to solder to if you’ve put pins in all the holes? WHERE???

Turns out I wasn’t reading the instructions closely enough.

In addition, I was attempting to solder things while the board was embedded in the case. That didn’t work to well either. There was nowhere for the iron to really fit. While I was at it, it reminded me that I was using a very cheap soldering iron that I had only bought for something to do heatset inserts with, which wasn’t as precise or controllable as I needed.

So, with all that, I decided to make a few changes to my process and equipment.

1. I reprinted the case. I’d… kinda melted the board into the original case already and couldn’t get it out.

2. I carefully reread the instructions, found a diagram of the pinout for the board, and made myself a detailed diagram to work from before soldering ANYTHING.

I only needed a few of the pins that came with the board to make things to mount the board to the case, not the entire row.

3. I used thinner, more flexible wires. The originals were waaaaay too inflexible to fit where I needed them.

4. I did all my soldering away from the plastic, then carefully installed the parts in. No unintentionally melted plastic.

5. I improved my soldering equipment and process. I made liberal use of solder flux (I’d shied away from it in the past), added a fume extractor to avoid having to work with the door open, and got a much better soldering iron after conferring with other makers about their recommendations. It was my third iron after all, it was time to get something that would work well. Finally got myself a Hakko.

Also took a little bit of time to do some reading/viewing so I’d take better care of this iron and have better soldering results.

This was a series that helped me, by the way. Sometimes you gotta go back to basics… and realize your bad habits that you’ve gotta fix.

6. For connecting to the joystick, I used solderless connections to save my sanity, since it came with connector pins on the stick already.

Anyway, after all that on the hardware side, I finally got the thing built. All the wires soldered, the thing assembled and closed up.

I used black for the optional button extensions because I thought it’d be easier to use with contrast.

I ran into an issue with the thing slipping around on my glass desk, so I pulled out the rubber tape that I used for my arch lamp to make this nonskid as well.

Now it doesn’t move anywhere unless I deliberately pull it off the desk.

Once I got the thing assembled and plugged up to the computer, I loaded the code included with the instructable.

Buuuuut…

The code was written primarily for this thing to work with Autodesk Inventor not Autodesk Fusion 360. The shortcuts are different in those two pieces of software. It took a bit of reading (particularly looking up the shortcuts for Fusion, figuring out the Keyboard. h code, and the firmware itself), but I eventually got at least the ability to orbit (rotate the view around the models) and zoom to work.

… also kinda had to swap the X and Y axes in the firmware. I might have gotten those two pins swapped on install. It works now, though!

Once I’ve used it a bit more, and thought more on what commands I use frequently, I’ll have to take the time to reprogram the buttons to do something useful.

Anyway, I got a new toy, got some more experience on these kinds of electronics projects, and had a reason to finally upgrade my electronics setup to be something more useable. Win!

Note: Yes, I know that isn’t the common spelling for useable, but usable doesn’t look right to me, and IT’S A VALID SPELLING, DAMMIT.

[END OF LINE]